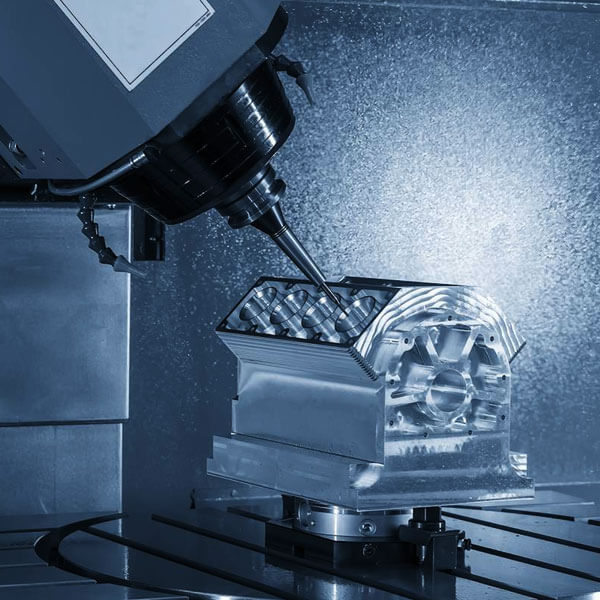

Enhancing component strength and efficiency through CNC machined perfection is a transformative approach that has revolutionized modern manufacturing and engineering. CNC Computer Numerical Control machining offers unparalleled precision, consistency, and versatility, allowing manufacturers to produce components that meet the highest standards of strength and operational efficiency. At its core, CNC machining leverages computer-controlled tools to remove material from a workpiece with exceptional accuracy, ensuring each part is crafted exactly to the specified dimensions and tolerances. This precision directly contributes to the overall strength of the component, as it eliminates the inconsistencies and defects that often arise with traditional machining methods. One of the most significant advantages of CNC machining in enhancing component strength is its ability to maintain tight tolerances. Components that fit perfectly within assemblies reduce stress concentrations and wear, which in turn prolongs their service life. For example, in aerospace or automotive industries where components are subjected to extreme forces and varying conditions, even a slight deviation from design specifications can lead to premature failure.

CNC machines can operate with micrometer-level accuracy, ensuring that parts are produced consistently with minimal variation. This consistency not only improves structural integrity but also boosts the efficiency of the entire system by reducing the risk of malfunction and the need for frequent maintenance. Moreover, CNC machining allows for the creation of complex geometries and designs that would be difficult or impossible to achieve through manual methods. These complex designs can optimize the distribution of stress within the component, enhancing its strength while potentially reducing its weight. Lightweight, high-strength components are particularly valuable in industries such as aerospace, automotive, and medical devices, where reducing mass can improve fuel efficiency, performance, and usability. By precisely controlling the shape and dimensions, CNC machining enables engineers to implement innovative design features such as internal channels for cooling, variable thickness walls for strength optimization, and intricate surface textures to improve bonding or reduce friction. Manual machining depends heavily on operator skill and experience, which introduces variability and potential mistakes. CNC machining minimizes this risk by automating the process and following pre-programmed instructions. This automation leads to higher repeatability and quality control, which means components perform reliably over time without unexpected degradation.

Additionally, CNC machines can run continuously with minimal supervision, improving production throughput and reducing lead times, which is crucial for meeting the demands of fast-paced industries. Furthermore, CNC machining supports the use of advanced materials such as titanium, hardened steels, and specialized alloys that offer superior strength and durability. The ability to machine these materials with precision opens new avenues for designing components that can withstand harsh environments and heavy loads without compromising efficiency. This capability also allows manufacturers to tailor components for specific applications, balancing strength, weight, and cost considerations more effectively than ever before. Through precision, consistency, design flexibility, and the ability to handle advanced materials, online cnc service empowers manufacturers to produce components that are stronger, lighter, and more reliable. This not only extends the lifespan and performance of individual parts but also contributes to the overall efficiency and sustainability of complex systems, ultimately driving innovation and excellence in manufacturing.