Outsourcing compliance monitoring enables businesses to optimize the efficiency of their operations and minimize risk. It also offers transparency and accountability. You should choose the service provider that is able to clearly define contracts, an exit strategy, and is committed to compliance with industry standards.

A comprehensive compliance program can be expensive, and failure to adhere can result in heavy fines and legal action. Third-party compliance tools can help limit the risks to reputation and finances by leveraging advanced technology platforms.

Outsourcing compliance with regulatory requirements

Outsourcing regulatory compliance offers brokers, financial companies, and RIAs the benefits of reduced costs, improved risk management, as well as technology-driven efficiency. They are also able to focus on their core business and expand quickly without having to worry about the expense of a compliance department. However, the process does not come without difficulties. For example, some companies fear losing control over compliance tasks when they partner with an external service provider. These concerns can be addressed with the help of shared systems as well as clear communication frameworks and important performance indicators, and also by establishing the governance and escalation structure.

Selecting a good outsourcing provider for compliance needs careful research and consideration. Choose a company that specializes in your industry and has a thorough understanding of the rules and compliance frameworks you use. Choose a firm which is proactive and provides continuous support.

The use of a third party to handle the surveillance of your compliance activities can increase accountability and transparency in your company. The most reliable companies for compliance outsourcing will provide thorough documentation and regular updates regarding compliance activities which reduces risks and provides total transparency. They will also assist you to identify and avoid regulatory risks before they become an problem. This is vital in avoiding legal action, as well as preserving your reputation among customers, investors, and partners. Moreover, a good outsourcing company for compliance can provide proactive guidance, which can aid you in reducing risk and reach your goals in compliance.

Monitoring compliance services

Every business has to monitor compliance; this includes adherence to internal policies, industry standards, and external regulations such as Corporate tax incentives for FDI in Vietnam. It is crucial to regularly examine and monitor the company’s compliance with its internal policies as well as industry standards, no matter if you work in an industry that is highly regulated or not. By doing so, it is possible to identify areas of non‑compliance and reduce the risk before they become serious problems.

This involves reviewing and evaluating your operations, activities, and processes to ensure that they comply with the requirements of regulatory compliance. This can be done manually or through automated systems. It’s an ongoing process that requires surveillance, review and analysis of the way your company performs as well as the risk factors that are involved. This helps teams address problems before they escalate.

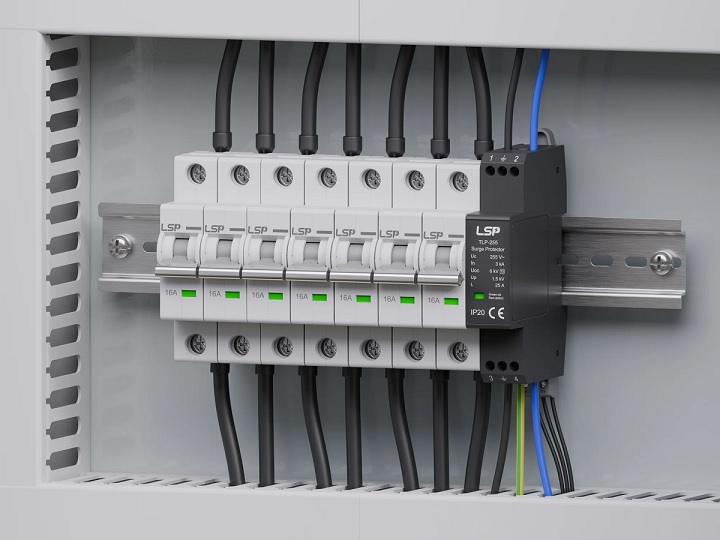

A strong monitoring system for compliance can help lower costs and enhance the performance of your company. Automated solutions can help accelerate compliance inspections. This can reduce the amount of time that employees spend working on manual tasks and allows them to concentrate on other tasks. Moreover, it can alert your team to potential problems in real time and help them address issues before they become large-scale compliance failures.

A quality compliance monitoring tool will seamlessly integrate with the existing systems to give an extensive view of compliance status across the organization. This will make it easier for you to track adherence to internal and external guidelines, and to avoid penalties from regulators. This should aid the activities of the legal, IT, finance, HR, and operations teams to help them coordinate their activities.

Third-party solutions for compliance

Third-party compliance solutions are a critical part of every business. They aid organizations in protecting their reputation and brand by ensuring that third-party compliance with laws or regulations and policies. They also offer one centralized platform to monitor compliance activities. This guarantees consistency and efficiency, minimizing the risk of legal disputes, fines for financial violations, or reputational damage. Ultimately, a robust third-party compliance system is a reliable way to build trust with stakeholders and protect long-term profits.

Third-party compliance solutions are software tool that allows companies to perform due diligence and monitor the activities of third parties. It helps in assessing risks posed by third parties, allowing businesses to make informed decisions regarding their suppliers, contractors, and even vendors. It helps businesses save time and money by eliminating manual processes.

The most commonly used third party is called a vendor, however it could be any other entity that has a relationship to a business. This includes distributors, suppliers, outsourcing agencies contractors, affiliates, and even consultants. Third-party compliance involves vetting and setting expectations, guidelines, and making sure they adhere to the same standards of compliance as their organization.

It is essential to select suppliers from third parties that have a proven track record and commitment to ethical business practices. This is done through due diligence and assessing their integrity, financial stability, and compliance records. It is also essential to monitor vendors continuously to identify any changes to their compliance status.

Outsourcing compliance comes with many advantages

The process of managing compliance can be costly. Hiring and training compliance staff will require a substantial investment, while sustaining systems and technology is time-consuming and expensive. Outsourcing can cut expenses and also provide access to specialist expertise. It also offers flexibility and scalability which allows companies to alter their compliance processes as their businesses grow.

Choosing the right outsourcing provider is essential. You must ensure that they are trustworthy and have extensive experience in the industry you are working in. Get references from their clients and case studies to assess their performance. In addition, ensure that they comply with all applicable laws and rules including privacy laws. Also, establish a clear dispute resolution procedure. This will reduce risks related to unforeseen events, such as litigation or settlements.

A third-party service provider can increase transparency and accountability in a company’s compliance processes. They will provide periodic updates and detailed documentation, so that everyone knows the progress of compliance initiatives. They can also prevent unintentional breaches by identifying weaknesses which might not be noticed within the company.

Outsourcing compliance can help you let resources go to be put to use for strategic projects as well as growth and innovation. But, it’s important to take into consideration the long-term effects of outsourcing compliance prior to making the decision. The communication of the reason for outsourcing is important. This will help ensure they are on board with the outsourcing process and will be supportive of its success.